Renew

A sustainable alternative to disposable blades

Objective: Create a more sustainable utility knife

Surveys

70%

of Designers prefer an X-acto knife

30%

of Designers forget to replace the blades

Edge Maintenance

Investigating ways that already exist that help consumers maintain a sharp edge quickly and easily

Ideation

Concept 1: Attached Sharpener

Concept 2: Clickable Blade

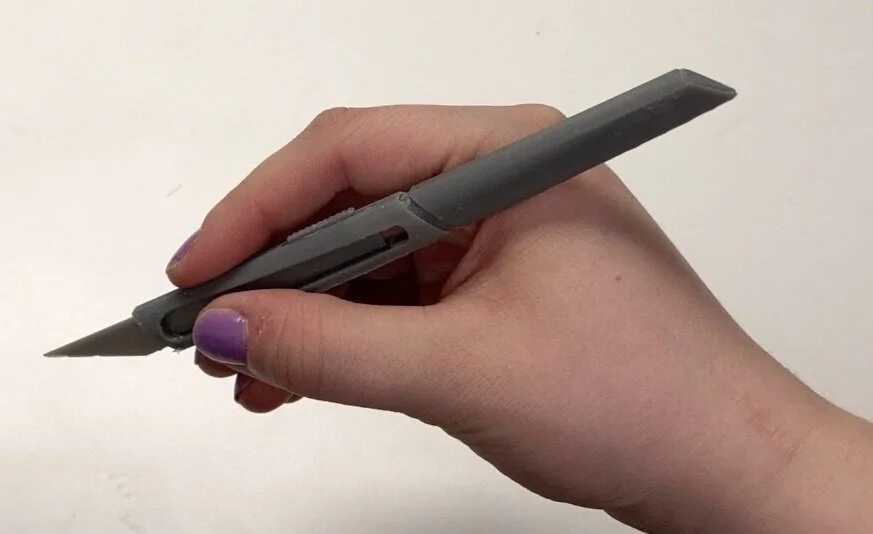

Rudimentary prototypes were made during ideation to figure out sizing and ergonomic factors.

A combination of 3D printed parts and regular pen parts. This helped achieve the recognizable “click” .

Mechanism

The classic utility knife button is difficult to make because it is too small.

SLA and FDM attempts to print the mechanism failed due to small size. There was no way for me to make these parts with the resources at hand.

New Slider

The Christy Knife has a sliding mechanism that utilizes a similar open gap in the middle

The patent is now public domain

This was chosen as the new mechanism

Slider CAD

Final Prototyping

I made my own version of the Christy sliding mechanism, and while it is still too small to feasibly work as SLA parts, it provides a good demonstration of what the product’s intentions are.

A hacksaw blade was ground down into a long X-acto blade that would fit into the knife. This unique longer blade can be continually sharpened.

Features and Rationale

Longer sharpen-able blade: Sustainable, replace less blades, sharpens like a Japanese blade

Electroplated diamond stones: Durable, lasts a long time

Angled design, thin blade : Allows user to have a high level of control over their craft

Familiar Mechanisms: Easy, No high level of skill needed to use

Blade Protection: Both the user and the blade are protected when not in use